Data loss can be a nightmare, especially when important documents, photos, or work files suddenly become inaccessible. One common reason for hard drive failure is a faulty Printed Circuit Board (PCB). In such cases, hard drive PCB replacement for data recovery can be a viable solution. However, it’s not as simple as swapping boards — there’s a lot more to consider.

Understanding the Hard Drive PCB

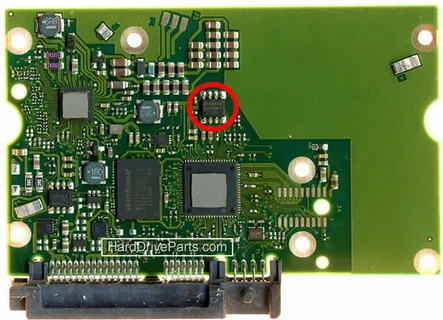

The PCB is the green (or sometimes blue) board on the underside of a hard drive. It controls the power supply, communication with your computer, and operation of internal components like the read/write heads and platters. When this board is damaged — due to power surges, overheating, or physical impact — your drive may stop working entirely.

Signs Your Hard Drive PCB May Be Faulty

Before you attempt a hard drive PCB replacement for data recovery, it’s essential to confirm the PCB is the issue. Common signs include:

- Drive not spinning or making any noise

- Burning smell or visible damage on the board

- Drive is not detected in BIOS or by your operating system

- Clicking or beeping sounds on startup (though these can also indicate internal damage)

Why You Can’t Just Swap PCBs

Unlike older hard drives, modern drives have unique microcode, calibration data, and firmware stored on the PCB or even embedded in a ROM chip. This information is specific to each drive and is required to access the data. Therefore, if you simply swap the PCB with one from the same model, the drive still may not work.

To perform a proper hard drive PCB replacement for data recovery, you’ll often need to:

- Find an exact donor PCB (same model number, firmware, and manufacturing date)

- Transfer the original ROM chip from the damaged board to the donor PCB

- Test the drive with the new PCB

Professional Help vs DIY

If you have soldering skills and access to the right tools, a DIY replacement might work — but there are risks. A mistake during ROM chip transfer can permanently damage your data. For critical files or irreplaceable data, it’s best to consult a professional data recovery service.

Many data recovery experts specialize in hard drive PCB replacement for data recovery and have access to donor boards, specialized tools, and software for firmware reconstruction and data extraction.

Cost Considerations

Replacing a hard drive PCB is often more affordable than full-scale recovery from internal platter damage. However, prices can vary depending on the drive type, complexity of the issue, and the availability of a matching PCB. DIY replacements may cost $30–$100, while professional services may range from $200 to $600 or more.

Conclusion

A failed hard drive doesn’t always mean lost data. In cases where the PCB is the culprit, hard drive PCB replacement for data recovery offers a practical solution. Whether you go the DIY route or seek professional help, understanding the technical complexities involved can save you time, money, and your valuable files.