As the semiconductor industry faces increasing complexity in both scaling and system design, it is casting a wider net for enabling technologies. Once viewed as niche components, Microelectromechanical Systems (MEMS) and Microoptoelectromechanical Systems (MOEMS) are now stepping into broader roles, extending well beyond their traditional boundaries. Erik Hosler, a consultant with extensive experience in EUV lithography and semiconductor research, points out that this growing trend was discussed during discussions at the SPIE lithography conference, where patterning and device architecture intersect with new domains.

The shift toward embracing MEMS and MOEMS reflects more than just an appetite for innovative ideas. It reveals how industry roadmaps are being redefined around diversity in integration, physical functionality, and heterogeneity. As Moore’s Law slows, engineers are no longer focused solely on shrinking transistors. They are looking at how multiple types of components can be packaged together to create smarter, more efficient systems that interact with the real world.

From Peripherals to Pillars

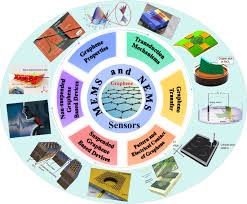

Traditionally, MEMS were deployed in functions like motion detection, pressure sensing, or timing. MOEMS found homes in projection and optical switching applications. These were indispensable technologies but typically remained peripheral to core computing tasks.

That paradigm is changing. Now, MEMS and MOEMS are considered integral to chip architecture. In systems-in-package approaches, these components can offer unique mechanical or optical capabilities directly within computing systems. For example, MEMS gyroscopes and pressure sensors are now embedded within mobile and automotive chips, while MOEMS components such as micromirrors are being evaluated for on-chip optical communication and beam steering.

This expanded role is particularly important in environments where size, power efficiency, and integration density are critical, such as in biomedical devices, wearables, and edge computing.

A More Inclusive Roadmap

This development did not happen in isolation. It came from a deliberate broadening of focus in industry discussions and research priorities. At the SPIE lithography conference, Erik Hosler remarks,

“Last year, we included MEMS and MOEMS, and we will keep expanding to quantum to make this a place to ask questions … Lots of great things are going on, and something will emerge.”

It reflects an important change in mindset. Semiconductor advancement is no longer driven only by traditional scaling. New functionality and integration possibilities are equally important. MEMS and MOEMS bring dimensions of sensing, motion, and light manipulation that are increasingly relevant across applications, including chiplet interconnects, adaptive optics, and environmental interaction.

The fact that they are now a consistent topic of discussion in major roadmap events shows that the industry is recognizing their long-term value.

Integration Complexity Brings New Design Paradigms

Incorporating MEMS and MOEMS into mainstream semiconductor flows introduces process and integration complexity. MEMS fabrication often requires steps that diverge from standard CMOS flows, such as deep reactive ion etching or high aspect ratio structures. MOEMS may involve reflective coatings or precise cavity formations that challenge lithographic alignment.

Two main integration strategies have emerged to bridge these gaps. Monolithic integration allows MEMS structures to be built directly on top of CMOS circuitry. It provides performance and footprint advantages but requires significant adjustments to front-end process modules. Alternatively, heterogeneous integration assembles separately fabricated dies into a single package using advanced bonding and interconnect techniques.

Each approach presents tradeoffs in terms of thermal budgets, yield, alignment precision, and manufacturing cost. As a result, semiconductor design tools and methodologies are adapting to accommodate mechanical and optical components within what were once strictly electrical design workflows.

Optical and Photonic Applications are Driving MOEMS Growth

One of the most active areas for MOEMS development is optical interconnects and integrated photonics. As data rates in computing systems continue to rise, electrical interconnects struggle with limitations in bandwidth, latency, and power consumption. Optical links offer a compelling alternative, and MOEMS are emerging as key enablers of dynamic alignment, modulation, and signal routing.

Applications such as on-package optics, optical neural networks, and silicon photonics rely on precisely controlled beams, switches, and mirrors. MOEMS can provide the needed control at scale and with compatibility with wafer-level packaging. Their ability to support adaptive, reconfigurable systems is particularly attractive for future architectures based on chiplets and optical chip-to-chip communication.

As systems demand higher performance and flexibility, MOEMS are increasingly positioned as both enablers and differentiators.

Broader Use Across Multiple Industries

MEMS and MOEMS are also gaining momentum across a diverse set of industries. In the biomedical field, MEMS devices are used in drug delivery systems, implantable pressure sensors, and lab-on-chip platforms. In automotive systems, the MOEMS lidar is becoming a foundational technology for environmental mapping and autonomous navigation.

These cross-sector applications pressure the semiconductor ecosystem to provide scalable, manufacturable platforms that can support diverse form factors and performance envelopes. MEMS and MOEMS are not just enabling new products. They are also influencing how fabs, design tools, and testing infrastructures change. As these technologies mature, their compatibility with mainstream semiconductor processes will be critical to unlocking broader adoption.

Laying the Foundation for Emerging Technologies

The mention of quantum systems alongside MEMS and MOEMS is not a coincidence. Emerging quantum technologies often depend on mechanical and optical precision at the nanoscale. For instance, MEMS-based resonators are being investigated for use in quantum sensors, and MOEMS mirrors and modulators play roles in manipulating photons in quantum communication and computing systems.

Fabrication of these components requires the same kind of control and integration expertise that the semiconductor industry has developed through decades of MEMS and MOEMS work. Their continued progress could provide a bridge from classical electronics to hybrid classical-quantum systems.

In this context, expanding the roadmap to include MEMS and MOEMS is not just a diversification strategy. It is a long-term investment in technologies that may become central to the next computing paradigm.

A More Functional Future

The expanding role of MEMS and MOEMS is redefining what is considered core in semiconductor development. These technologies enable new types of interaction with the physical world through motion, pressure, light, and more than traditional digital logic can achieve alone.

Their integration into roadmaps and mainstream design discussions reflects a future where chips do more than compute. They will sense, communicate, adapt, and operate in complex environments with greater autonomy and efficiency. As semiconductor progress becomes increasingly multidimensional, MEMS and MOEMS are not just useful. They are becoming essential.